|

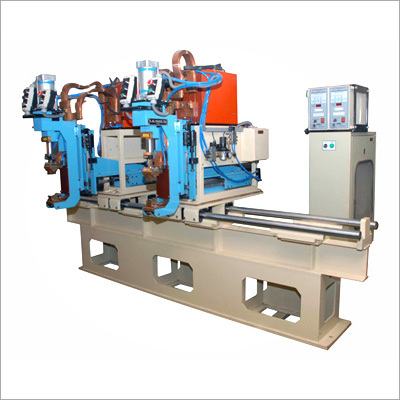

Fully Automatic Copper Braid Solidification Machines

Fully Automatic Copper Braid Solidification Machines Specification

- Product Type

- Fully Automatic Copper Braid Solidification Machine

- Material

- High Conductivity Copper

- Capacity

- Up to 80-120 kg/hour

- Computerized

- Yes

- Automatic Grade

- Fully Automatic

- Control System

- PLC Controlled

- Processing Type

- Solidification and Forming

- Voltage

- 380V/415V, 3 Phase, 50/60 Hz

- Power

- 12 KW

- Dimension (L*W*H)

- 3200 mm x 1100 mm x 1800 mm

- Weight

- 1600 kg

- Color

- Industrial Blue/Grey

- Operating Temperature Range

- 0°C to 50°C

- Max Braid Width

- Up to 120 mm

- Production Line Integration

- Yes, compatible with automated lines

- Input Braid Diameter Range

- 2 mm to 30 mm (customizable)

- Safety Features

- Overload Protection, Emergency Stop

- Cooling System

- Integrated Water Cooling

- Main Application

- Copper Braid Compaction & Soldering

- Lubrication System

- Automatic Lubrication

- Display Type

- Touch Screen HMI

About Fully Automatic Copper Braid Solidification Machines

Advanced Solidification Technology

Experience superior copper braid compaction and forming with cutting-edge technology. The machines high-conductivity copper processing, automatic lubrication, and water cooling systems ensure optimal operation and product quality in high-demand manufacturing environments.

Seamless Integration with Production Lines

This fully automatic system is designed for streamlined integration with modern automated production lines. Rapid setup and flexible compatibility reduce downtime and adapt easily to evolving manufacturing needs, making it a reliable choice for large-scale operations.

User-Friendly and Safe Operation

Featuring a touch screen HMI for straightforward control and real-time monitoring, this machine also includes safety mechanisms such as overload protection and an emergency stop system. Operators can confidently manage processes with minimal risk and maximum comfort.

FAQs of Fully Automatic Copper Braid Solidification Machines:

Q: How does the fully automatic copper braid solidification machine enhance copper braid compaction and soldering processes?

A: By utilizing PLC-controlled automation, integrated water cooling, and an automatic lubrication system, the machine consistently delivers robust compaction and precise solidification or soldering. This optimizes productivity, efficiency, and finished product reliability.Q: What are the main benefits of using an integrated water cooling system in this machine?

A: The integrated water cooling system effectively manages operational temperatures, preventing overheating and ensuring stable performance. This extends the equipments lifespan and maintains consistent quality in copper braid processing operations.Q: When should I consider integrating this machine into my production line?

A: If your manufacturing requires high-volume, continuous copper braid compaction and soldering, or if you seek to improve efficiency and automation, integrating this machinecompatible with automated linescan significantly enhance productivity and reduce labor costs.Q: Where can this solidification machine be effectively utilized?

A: This machine is ideally suited for industrial facilities involved in manufacturing electrical cables, automotive components, or any application demanding high-capacity copper braid forming and soldering, particularly where high reliability and automation are required.Q: What is the typical process workflow of the machine?

A: Copper braid with diameters between 2 mm and 30 mm is fed into the machine, which compacts and solidifies or solders the material under a controlled PLC system. Integrated sensors, lubrication, and cooling systems maintain operation standards throughout.Q: How does the touch screen HMI benefit operation and maintenance?

A: The touch screen HMI offers a user-friendly interface for quick set-ups, real-time monitoring, and easy parameter adjustments. It also provides instant alerts and diagnostics, facilitating efficient maintenance and minimizing production interruptions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Special Purpose Machine Category

Fully Automatic Drums and Barrels Mash Seam Welding Machines

Weight : Approximately 1800 kg

Material : Highquality industrialgrade metals

Dimension (L*W*H) : Customizable as per requirements

Voltage : 220V440V

Control System : PLC (Programmable Logic Controller), Other

Color : Blue

Automatic Radiator Seam Welding Machines

Weight : Heavy

Material : Metal

Dimension (L*W*H) : Custom Dimensions

Voltage : 220V

Control System : Other, Electromechanical

Color : Green

Multi Tips Spot Welding Machines

Weight : 500 kg

Material : Mild Steel

Dimension (L*W*H) : 1200 x 600 x 1500 mm

Voltage : 415 V

Control System : Manual, Other

Color : Green

Projection Welding Guns for Balance Weight Welding

Weight : HeavyDuty Equipment

Material : HighGrade Steel

Dimension (L*W*H) : Customizable

Voltage : 380415 V

Control System : Electronic Control System, Other

Color : Multicolor (Blue Orange Cream)

|

S. M. ENGINEERING CO.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry